Cacao Creativity

Harvest Husks for a Sustainable Solution

In a world where climate change is accelerating and concerns over environmental resources abound, the need for innovative, new solutions has never been greater. Enter fish scales, sugarcane, algae and cacao. A seemingly motley mix, they nonetheless have something in common—a creative attempt to reduce plastic packaging. Over the past few years, these renewable, organic materials are helping researchers and entrepreneurs envision a future in which these very materials constitute the basis of our everyday products.

In particular, innovative work is being done in Peru to commercialize and scale the use of cacao husks for biodegradable packaging. This momentum comes as other scientists and engineers around the world continue to experiment with different types of raw natural materials, such as the algae, sugarcane, and fish remains mentioned above. Now, the young Peruvian entrepreneur Alejandra Cuba Canales has been repurposing leftover cocoa husks in her home country. Her two-year-old startup, Caopack, is coming at a time when innovative new solutions are needed to address the impending climate crisis.

The problem with plastic continues to become more apparent each year, scientists warn. Last year, PBS reported that by 2050, there will be more plastic in the ocean than fish. In March 2020, Bloomberg came out with a piece describing that about 80% of all the plastic that has ever been produced is sitting in a landfill—and will remain to do so for hundreds of years.

The Covid-19 pandemic too has wrought its own environmental challenges, particularly evident in the images of plastic grocery bags billowing in the wind as many shift to single-use packaging for sanitary reasons. Therefore, as people contemplate how we will “rebuild better” after the pandemic, making sure that concerted efforts are taken to also reduce plastic are needed.

Natnael Behabtu, a Global Technology Leader in the Biomaterials division of DuPont, explains over email that there are essentially two types of biomaterials. The first are materials that have polymers with the same chemical composition as petroleum-based polymers that are currently being used. Given that they are equivalent, these new biomaterial polymers can be used as a direct replacement during production. The other type of biomaterials are new, innovative chemical compounds, but they cannot simply be used as substitutes. While both of these alternatives will be more expensive than traditional materials, the second type of novel polymers will require revisioning and altering current production practices given that it cannot be directly substituted. However, he explains, these new materials can be influential in reducing reliance on and usage of petroleum-based materials and structurally changing supply chains.

And although it might sound like a futuristic vision, the idea of everyday packaging being made from cacao husks is slowing becoming more of a reality. Scientists have indeed been thinking about this possibility for the past few years. In Europe, the company LeafLAB designed a line of cocoa paper and cocoa fibers, which can be used in cardboard products. The UK-based company James Cropper also developed a recycled paper using cacao husks back in 2013. Yet despite these early efforts, they have yet to become widely adopted or mainstream and are largely based in Europe, further away from where the cacao is often grown and harvested.

That is where Caopack comes in, a Latin American-based solution looking to prove that cacao-based solutions can be a competitive packaging alternative offered on the market. The company also uses a great percentage of raw material—at least 45% cacao husk—whereas some of these European competitors use less, with James Cropper using only 10% cacao in their product.

Cacao plantation in the Peruvian Rainforest. Photo by Alejandra Cuba Canales (2018).

Fermented cacao beans from the Peruvian Rainforest. Photo by Alejandra Cuba Canales (2018).

Going Back to the Roots: How Caopack Started

Born and raised in Lima, Peru, Cuba is a self-confessed chocolate lover. As she explained over a video call with a hearty laugh, from a young age, she was enamored by chocolate. It was the one thing she would always want to eat. White chocolate, dark chocolate, 70% cacao…there were so many varieties, she could never get enough, she confesses.

Alejandra Cuba Canales at Start-Up Chile in Santiago. Photo by Alejandra Cuba Canales (2019)

She would carry this sweet tooth with her as she started studying for her bachelor’s in industrial engineering in 2013. While at school, she had an eye-opening opportunity to study abroad in Spain. She was struck by the sustainability efforts that she encountered. Unlike her native Peru, where the environmental movement was more nascent, Spain’s cultural environmental consciousness was “years ahead,” she explained. During this time, she took classes with local students studying sustainability, and this sparked a desire within her to bring a culture of recycling back home.

In 2018, sometime after she returned from Spain, she signed up for an incubator class at her school, where students were encouraged to create a new product or solution. With her experiences from Spain in mind, Cuba wanted to tackle the sustainability problem by exploring bio-material packaging. Partnering up with a classmate and friend Mary Kei Rojas, the duo first dove into the science and production of another tropical crop endemic to the region—plantains. The aim: to create a bioplastic using plantain residue that would be biodegradable and anti-microbial. While initial iterations were appealing (no pun intended), there were some challenges. The material quickly oxidized, making it difficult to design for an attractive color, and getting the desired anti-microbial properties was costly. In short, they need a new material, one that could last longer and would be better suited for their packaging vision.

They went back to the drawing board, and that is when Cuba’s childhood passion was revived. While plantains posed challenging for large-scale manufacturing and product development, cacao shells provided an attractive alternative. Cacao husks last much longer than plantain peels, making it easy to store and transport the material. Additionally, the resource was plentiful and the opportunity for impact was great in Lima. Cuba explains that over the past several years, increased demand for chocolate with a higher percentage of cacao in Peru has meant that more cacao has been brought into the major cities for processing.

Buckets of fresh cacao beans from Peruvian Rainforest. Photo by Alejandra Cuba Canales (2018).

But while there is now a large number of chocolate production factories in the capital, there are not many options for recycling, composting or reusing the husks. So, despite the tremendous amount of biproduct that was produced, the lack of market or use for the cacao shells meant that they were largely thrown into the trash. Researchers write that only 33% of the cacao pod is harvestable fruit, and the remaining 67% is considered waste. This means that for every ton of cacao beans produced, approximately 10 tons of cacao husk are generated as waste.

Drying process for fermented cacao beans from the Peruvian Rainforest. Photo by Alejandra Cuba Canales (2018)

Seeing the tremendous potential of this material and recognizing the negative environmental effects of generating such waste, they switched to cacao, getting promising initial results. Working alongside other researchers in the Fruit and Vegetable Research Circle at the Faculty of Food Industries (CIFHFIA) and with the continued mentorship of Professor Luis Fernando Vargas Delgado, a packaging specialist, Cuba explains that she decided to continue working on this project after her classes ended. By November 2018, she had promising prototypes that would form the basis of the company and its patent. Her co-founder Rojas decided to pursue an opportunity at an already established company and has since been working on quality management at manufacturing companies. Over the next two years, Cuba would recruit a small team to help her, including Lesslie Palpa Diaz, research and development assistant, Diego Pozo, production assistant, and Jazmin Cuba Canales, public relations and social media lead.

Hidden in the Husk: The Search for a Solution

As many biodesigners and scientists know, it is one thing to find a promising solution in the lab, and quite another to scale that product for industrial use. While preliminary iterations of the biopackaging were promising, the question remained on how well this material would perform in real-world applications. How would the material withstand heat? Would it quickly break down when wet? More testing and development was needed.

With these questions in mind, Cuba applied to Jump Chile, a program tailored for entrepreneurial students with promising ideas organized by leading innovation centers and universities in Chile. This allowed her to validate the product with five companies in Peru, giving her good insight and perspective on product direction. By April 2019, the company was at the laboratory stage and had caught the eye of groups across Latin America, she says. Caopack was accepted into the yearlong StartUp Peru program as well as StartUp Chile in August 2019. Both are government programs designed to support entrepreneurship, with StartUp Chile being recognized as one of the top accelerators globally. Excited for this next international step, Cuba packed her bags—and her cacao—and moved to Chile in September 2019 for a four-month long incubator program.

This is when product development really accelerated. As Cuba explains, she arrived knowing about production inefficiencies she was eager to resolve. During this time, she optimized production, reducing her costs by 80%. And people were starting to take notice—she was selected to travel internationally, for example, to Paraguay for the annual WeXChange conference, promoting female entrepreneurs in STEM and to Uruguay for the Proyecta Uruguay for a pre-acceleration program. Caopack also participated in EXPO Patenta, run by the Peruvian government’s Directorate of Inventions and New Technologies (DIN), where she won prize money that allowed her to register for a patent. Eager to continue the progress she was making during this time, she applied for and was accepted to an extension program run by StartUp Chile that allows participants to stay three months longer (January-March 2020). In the beginning of 2020, she was also selected to present at the APEC 2020 Malaysia conference. Luckily, she was able to make the trip and wrap up her work in Chile before coming back to Peru as the Covid-19 outbreak unfolded.

Group photo of the organizers and selected participants for the ‘Young Entrepreneur Kick-Off” event in Malaysia, 2020 held by Asia-Pacific Economic Cooperation (APEC) Malaysia. Photo from SMECORP Malaysia, Young Entrepreneur Kick Off 2020.

Caopack has quickly demonstrated the potential of cacao as a biomaterial, particular in Latin America where the husks are plentiful. The company has worked with more than 25 small businesses to test its concept and is experimenting with other biomaterials as well.

Cuba reports that Caopack has raised more than USD $45,000 in equity-free financing since August 2018 and has already received a patent for its technology.

Beneath the Shell: An Inside Look at How it Works

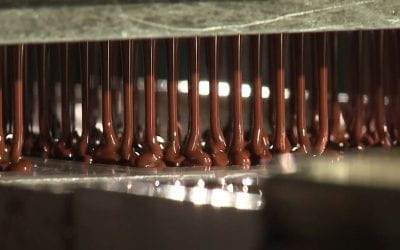

Making biomaterial from cacao has involved a research and development phase that took Cuba to the rainforest—to visit the cacao production sites; to the heart of Lima—to watch the chocolate production in the factory; and to the lab—to refine and perfect her prototype.

When working with this material, there are many important things to consider. As Professor Delgado explained over Zoom, cacao-based biomaterials can be a difficult to scale and produce at a large volume, and they cannot be used in all applications. However, cacao does have very good compostable properties, and the husks are plentiful in Latin America. Behabtu also writes that developing the proper oxygen, moisture, and light barrier for the material is a necessary part of developing the product for industrial applications. If correctly done, this material has the potential for both rigid applications—like aluminum containers—and flexible applications—such as multilayer polymer packaging.

Therefore, a lot of experimenting in the laboratory and during StartUp Chile was needed. Cuba describes how her product development made rapid progress in Chile when the company bought a small-scale dryer. This allowed for material optimization and refinement, although also presented some obstacles, she says. For one, the color of material needed to be taken into consideration. Given the original hue of cacao, all of the packaging was extremely dark. Unlike many other typical packaging manufacturers in the industry, Caopack is all-natural. Therefore, the company chose to refrain from the standard bleaching practice that others currently use and instead retain the natural color.

The other counter-intuitive challenge, she explains, was smell. While chocolate aficionados might want all of their packaging to smell like chocolate, there can be downsides. As Cuba explains, certain merchandise, particularly food items that do not taste like chocolate, might not benefit from having a chocolate-scented wrapper that can influence the flavor. Therefore, they were able to find an all-natural technique to reduce the scent without the use of chemicals.

Exterior view of Valkiria Chocolate (70% cacao) produced by the organic chocolate company Niva, from Kimbiri, Peru. Caopack supplied the company with an interior lining that wraps around the chocolate. Photo by Alejandra Cuba Canales (2019).

Interior view of a packaging, showing Caopack’s smooth wrapper around the chocolate bar. Photo by Alejandra Cuba Canales (2019).

Given the eco-friendly focus of the company, the product also needed to be easily decomposed, Cuba explains. It only takes a week for the current Caopack material to break down, and it can technically be consumed by users given its all-natural inputs. As Professor Delgado described over a Zoom call, there is a difference between being biodegradable and being compostable. Something that is compostable is also biodegradable, but it is not necessarily the other way around. This subtle nuance is important, because there are some biodegradable products that require industrial composters in order for the constituent parts to break down. If there are not the proper conditions, then it could take these biodegradable products as long as regular plastics to breakdown. This is especially a challenge in Peru, he describes, because these industrial composting facilities are not readily available or accessible. On the other hand, if something is compostable, then it means that when placed in a composting environment, the material will natural decompose often within the 90 breakdown cycle, therefore making it much more effective. Caopack’s products are compostable, and the paper-like material that the company has made has high permeability, allowing for improved composting. It also has a similar value and consistency to paper, with the added benefit that they do not cause deforestation.

Additionally, Professor Delgado notes that one of the challenges in Peru is that there are not many laboratories that certify a material as biodegradable, partially driven by the lack of awareness of and demand for biodegradable materials. These tests, he explained, are important for ensuring that product applications are consistent with the international, technical definition of biomaterial. However, this testing process can also be a bit involved. For example, to be biodegradable, the material must be 90% biodegradable within six months and needs to pass certain eco-toxicity thresholds. Conducting these evaluations therefore requires a dedicated team, with the proper space and equipment, who can study the product as it breaks down over a longer period of time. Having products like Caopack that can raise consumer awareness—and eventually demand—for biodegradable products will be instrumental for putting in place the proper infrastructure and capacity for environmentally-conscious practices.

Recently, Cuba has also started working with other raw materials to find additional biodegradable solutions. Cuba notes that when selecting for a new input, she tries to retain the authenticity of the original product by ensuring that there is at least 45% of the raw item in the final product. So far, she has developed packaging prototypes using pecan shells, passion fruit peel, pistachio shells and nut shells. But technical production considerations must also be taken into account, she observes. While she extols the characteristics of nut shells, she admits that producing them in Peru is more challenging than Chile, given the lack of nut processing plants.

Another important part of product development, as Professor Delgado explains, is cost. Every additional step in the manufacturing process increases the price. When working with a raw material, it is necessary to extract only the useful constituent pieces. Isolating cellulose and removing other liquids in products like oranges and lemons, for example, is critical to get the desired base ingredient. However, this also adds to the material cost. As he described, a traditional plastic bag costs less than two Peruvian sol cents, meaning it is extremely hard for the new biomaterials to be as price competitive.

Using the company’s current cacao husk material, Caopack will sell directly to businesses by creating packaging for a store’s products. Cuba will often find chocolate companies that appear to be interested in sustainability and reach out to see if they would be interested in running a mini-pilot, in which Caopack tests packaging tailored to the company’s specific merchandise. Most of its work has been with small and micro-companies, creating customized containers or wrappings. Examples include jewelry bags, cupcake wrappers and chocolate bar wrappers. The team is also exploring a partnership with large beer companies, such as Corona, to develop products like business cards and signs from spent grain (bagasse) from beer production.

Biodegradable jewelry bag made by Caopack. Photo by Alejandra Cuba Canales (2020).

Chocolate coins wrapped in Caopack’s biodegradable material, made from cacao husks. Photo by Alejandra Cuba Canales (2019).

Covid-19 has dampened partnership and production opportunities for Caopack, as it has for many companies. Cuba explains that some new engagements were put on pause, but overall, she is still optimistic about continuing to develop her products moving forward. Her vision continues to be focusing on Peru in the short term, to increase local sustainability, and then expand more broadly into Chile, Mexico, the United States and Europe.

Bar of chocolate (30 grams) in Caopack’s rough, biodegradable wrapper. Photo by Alejandra Cuba Canales (2019).

To achieve the company vision of creating flexible materials that can be competitive in the industrial packaging market, focusing on scaling and cost efficiency will be critical, she says. Success will depend on getting medium-sized businesses as customers and ensuring that Caopack’s materials can be rapidly produced at a large enough volume to meet the demand of various customers at once. While Caopack is still focusing on smaller, artisan companies in Peru and the region, scaling up is what Behabtu identifies as one of the greatest challenges for fledging companies in the material development space. Startups catering towards industrial customers must have the ability to produce a tremendously large volume to match the thousands of tons of packaging the customers use per year. Doing so requires significant capital investment as well as extensive time and research to properly develop the product. As one can imagine, this is no easy feat for scrappy startups who often need to have a minimum viable product and prove market demand before they can get funding.

As the economic impacts of the virus continue to reverberate throughout the global economy, diversifying partner companies will also be critical for Caopack. Many micro enterprises are suffering due to the shelter-in-place orders and may either close or may not be able to afford more expensive environmental packaging. And while it is important to start working with sustainability-focused companies, the true test will come when trying to become a mainstream product and start working with regular companies that traditionally were not as aware of their environmental impact.

What started as a childhood sweet tooth has quickly become an innovative environmental solution. This coming year will be a pivotal period for the company—one in which it must test its ability to scale for industrial purposes and attract a broader base of customers. While it will take time to put all the pieces together, getting it right will mean doing what others have not—proving that cacao can make a versatile biomaterial with a wide variety of applications. And getting it right might just be the golden ticket.

For more information about Caopack, please visit its Facebook page, watch the company pitch and video on product applications, or get in touch at caopackenvases@gmail.com. To learn more about the entrepreneur, Alejandra Cuba Canales, you can visit her LinkedIn page or contact her at alejandra@caopack.com.

Fall 2020, Volume XX, Number 1

Isabelle Foster was a Fulbright research scholar to Paraguay from Stanford University (until Fulbright recalled its scholars because of Covid-19). She graduated Stanford in 2018 with her BA and in 2019 with her MA. She is a researcher on sustainable development and is particularly interested in innovation, entrepreneurship, and impact investing for economic and environmental solutions. During her time in Paraguay, she worked in the Presidential Delivery Unit with the National Innovation Strategy. In addition to her research, she is an avid rower and triathlete, is teaching herself guitar and has set her sights on visiting all the national parks in the United States. She can be reached at isabelle.foster@fulbrightmail.org or at her LinkedIn.

Related Articles

Chocolate: Editor’s Letter

Is it a confession if someone confesses twice to the same thing? Yes, dear readers, here it comes. I hate chocolate. For years, Visiting Scholars, returning students, loving friends have been bringing me chocolate from Mexico, Colombia, Venezuela, Ecuador, Peru…

El jardín pandémico

English + Español

Imagine the tranquility of a garden. With the aroma of flowers mixed in with the buzzing of bees and the contrast of shady trees against the fierce Paraguayan sun. From the intimacy of a family garden in which daily ritual leads one to water the plants, gather up the dry leaves…

What’s in a Chocolate Boom?

English + Español

Peru has a longstanding reputation for its quality cacao. In the past decade, it has also attracted attention as a craft chocolate hot-spot with a tantalizingly long list of must-try makers. Indeed, from 2015 through 2019, a boom of more than 50 craft chocolate…